Difference between revisions of "Denavit-Hartenberg Convention"

| Line 5: | Line 5: | ||

[[File:privres-raw.png|left|140px]] | [[File:privres-raw.png|left|140px]] | ||

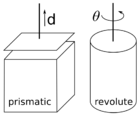

| − | Each manipulator has a certain amount of joints, that can be controlled. There are two types of joints used for robotic arms, each with one single degree of freedom. In the following the abstractions shown in the figure on the left will be used. The first type is the prismatic joint, that allows for translational movement along the joint axis. The displacement is described by the joint variable, for example <math>d</math> like in the figure. The second joint type is the revolute joint. A revolute joint allows for a rotation about the joint or rotation axis, respectively, and its joint parameter is the rotation angle, named <math>\ | + | Each manipulator has a certain amount of joints, that can be controlled. There are two types of joints used for robotic arms, each with one single degree of freedom. In the following the abstractions shown in the figure on the left will be used. The first type is the prismatic joint, that allows for translational movement along the joint axis. The displacement is described by the joint variable, for example <math>d</math> like in the figure. The second joint type is the revolute joint. A revolute joint allows for a rotation about the joint or rotation axis, respectively, and its joint parameter is the rotation angle, named <math>\theta</math> in the figure. |

The Puma560 for example has three revolute joints (see figure). The spacial relationship between the links depends on the current joint parameters and so does the transformation of the end-effector with respect to the manipulators base frame. This transformation is of high importance for the control of a robotic arm as objects are to be grabbed at certain positions and for example [[Kinematics|kinematics]] is highly dependent on it. | The Puma560 for example has three revolute joints (see figure). The spacial relationship between the links depends on the current joint parameters and so does the transformation of the end-effector with respect to the manipulators base frame. This transformation is of high importance for the control of a robotic arm as objects are to be grabbed at certain positions and for example [[Kinematics|kinematics]] is highly dependent on it. | ||

Revision as of 11:48, 30 October 2015

| ← Back: Realization of transformations | Overview: Denavit-Hartenberg Convention | Next: Assigning coordinate frames → |

In the robotics field, one important aspect is the control of serial link manipulators or robotic arms, respectively. A serial link manipulator is a series of links connected with actuated joints, commonly with an end-effector attached to the last link. One of the most famous robotic arms is the Unimate Puma560, that is shown in the figure on the right.

Each manipulator has a certain amount of joints, that can be controlled. There are two types of joints used for robotic arms, each with one single degree of freedom. In the following the abstractions shown in the figure on the left will be used. The first type is the prismatic joint, that allows for translational movement along the joint axis. The displacement is described by the joint variable, for example  like in the figure. The second joint type is the revolute joint. A revolute joint allows for a rotation about the joint or rotation axis, respectively, and its joint parameter is the rotation angle, named

like in the figure. The second joint type is the revolute joint. A revolute joint allows for a rotation about the joint or rotation axis, respectively, and its joint parameter is the rotation angle, named  in the figure.

in the figure.

The Puma560 for example has three revolute joints (see figure). The spacial relationship between the links depends on the current joint parameters and so does the transformation of the end-effector with respect to the manipulators base frame. This transformation is of high importance for the control of a robotic arm as objects are to be grabbed at certain positions and for example kinematics is highly dependent on it.

The Denavit-Hartenberg convention covers methods to assign coordinate frames to the links of serial link manipulators and to describe the spatial relationship between them by four parameters. Using these methods, the transformation of the end-effector with respect to the manipulators base frame can easily be determined and used for further computations.

In the following subarticles the individual aspects of the Denavit-Hartenberg convention are treated in detail: